PMAer Nick Gendron is a Project Manager and Project Controls Scheduler with significant experience in power, aviation, pharmaceutical, information technology, transportation, healthcare, and hospitality industries. He is skilled at providing overall construction management, leading teams, reporting on budget and schedule, and successfully providing high-quality work.

What is the Integrated Project Delivery Method?

Integrated Project Delivery (IPD) is a method of executing a construction project in which all contractors and subcontractors agree upon goals and collaborate throughout the entire course of the project. Everyone who has a role on the project—no matter the size—is expected to participate in all meetings and assist should the need arise as all team members are equally invested in the outcome. The architect remains involved throughout the project, not just during the design phase. The engineers are present at every meeting. All are one—when one person fails, the whole team fails.

The objective is to avoid the usual back and forth that occurs when problems arise. For instance, when something goes wrong, the architect is present in the room and can immediately suggest a redesign rather than the contractor having to reach out and wait for a response. Claims and change order management are thus prevented because changes, discrepancies, design, and field conditions are all addressed in the moment, saving time and money and keeping the project on schedule.

IPD is an extremely effective method for executing complex projects since it so greatly reduces conflicts. However, a project must be set up as an IPD project from the start. Written into every contract must be the proviso that no single entity owns the float of the schedule or the cost contingency. This is an extreme case, but there have been discussions on jobs I’ve been on where the toilet partitioning subcontractor needs to be a part of the project when we break ground because the toilet partition contractor owns as much of the project as the architect, the excavation subcontractor, or whoever is working on this job. And we all own it together. As previously noted, the contracts are written to specify that you must be on site and available to participate in daily meetings.

Are there incentives to encourage this type of planning?

Incentives specifying that if the project is finished early then everyone gets more money are sometimes written into contracts. If the owner wants an IPD contract, the owner will write those monetary incentives into everyone’s contract to be split up evenly among all the contractors. But in reality, the most attractive aspect comes at the end of the job: if there is one claim, everyone loses, or if there are no claims on the project at all, everyone is successful. This process worked, issues were addressed as they arose with everyone in the room, and any associated costs were discussed from the start. For all those subcontractors that don’t like to make their money on change orders but would like to just get jobs done and get paid for them, this is a very attractive delivery method. Some contractors would never admit it, but they severely lowball a bid and then make up the money through change orders. That doesn’t work here because the change order processes are significantly reduced.

What is Pull Planning?

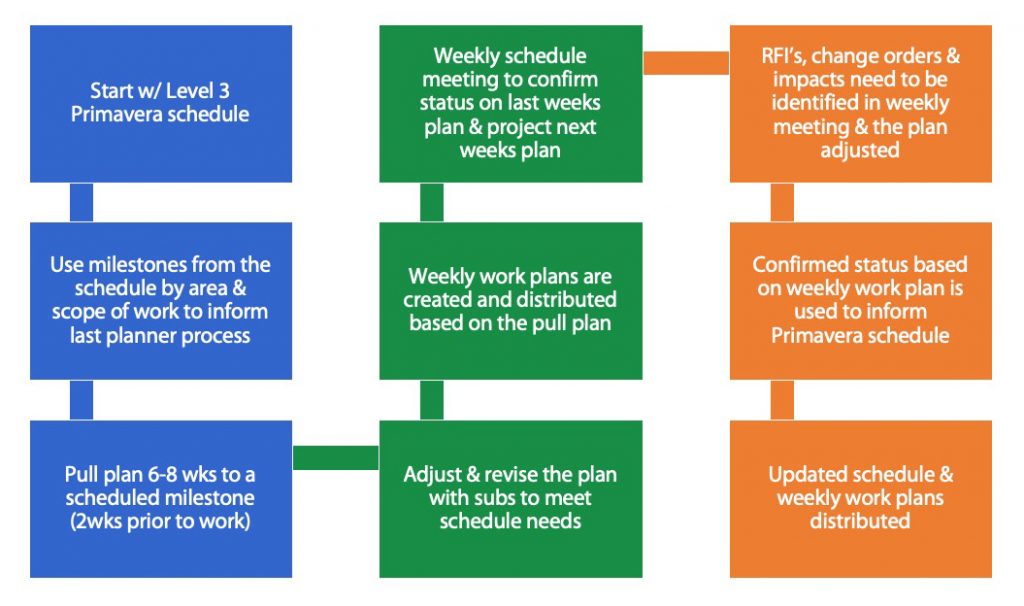

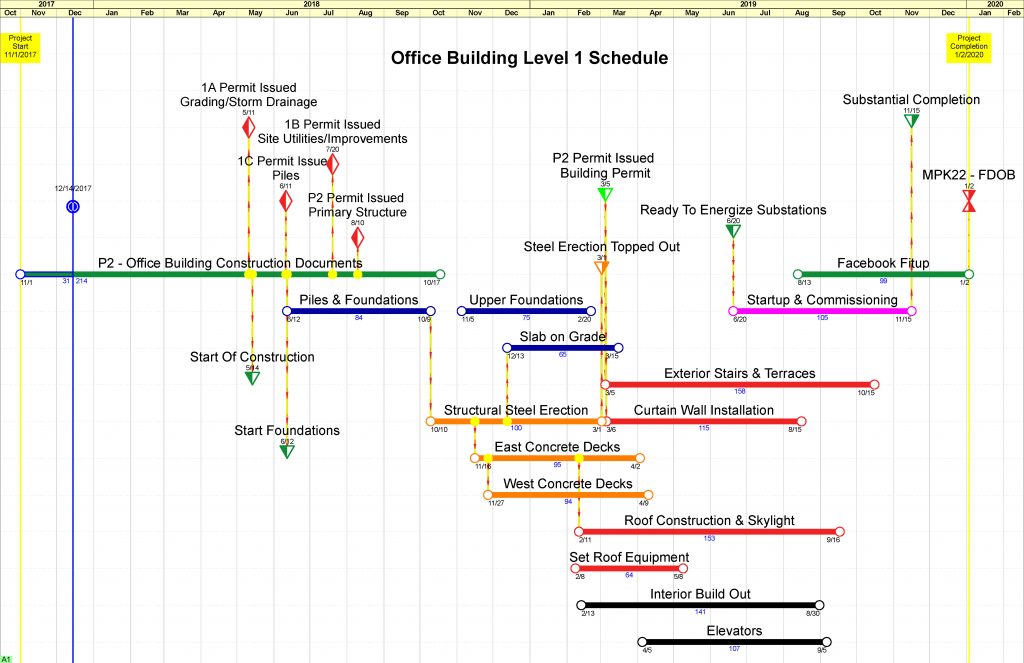

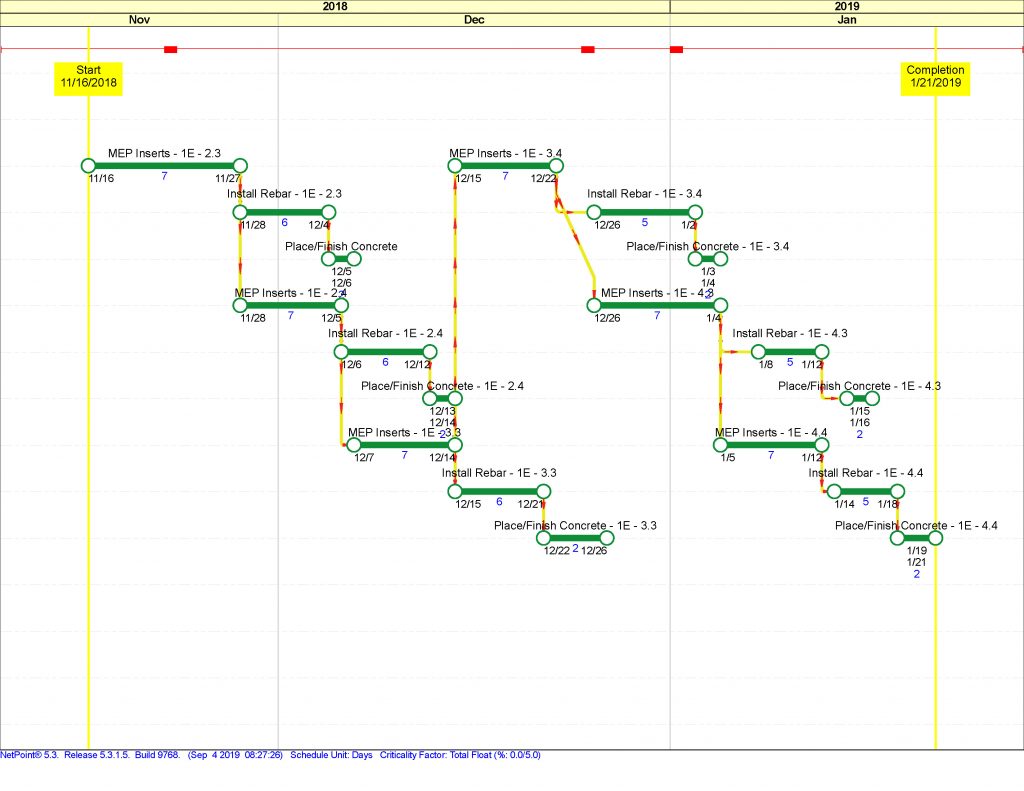

Pull planning, or short interval scheduling, is when you build your schedule by working backwards from goals. For instance, a general contractor will deliver a high-level schedule with milestones and rough durations. Then every couple of weeks all the subcontractors meet and schedule in minute detail all the tasks that need to happen over the course of the next four to six weeks to reach that milestone.

For example, at the start of a project, we will be pull planning for six weeks of the excavation process, foundations, and maybe underground utilities. So, I will have all my subcontractors that have anything to do with underground utilities, excavations, and foundations in the room and we discuss what milestone we need to reach in six weeks and work backwards to decide which tasks need to be done to meet that goal. If the goal is to finish the foundation in six weeks, we’ll need to pour and cure the concrete. Prior to that, we need to install rebar, and before that we’ll need to complete forms. We determine how much time each task will take and create a detailed schedule to accomplish our goal. It’s really effective because, since we’ve scheduled everything down to the details for each six-week period, the people working in the field have a very clearly outlined plan to work from.

How do Pull Planning and IPD work together?

Pull planning is an essential part of IPD and they work together because everyone is clear about their roles and responsibilities. The IPD process and the language in its contracts sets the expectation that each one of the stakeholders on the job is equal and we are all committed to working together throughout the entire project. That commitment includes pull planning. You will plan this job in a short interval pull-planning environment; you will be a part of all the meetings; you will update the schedule daily. Then every couple of weeks you’ll do a six-week short interval schedule with the team. So, the IPD process and the scheduling process go hand in hand. Everything is short interval, everything is transparent, and we as a team always communicate. We over-communicate. That’s how we get this job done.

What kind of projects benefit most from IPD?

I am a strong proponent for IPD and believe it can improve almost any project. Notably, complex projects, especially in the medical field, can certainly benefit. Those projects are so involved, so dependent on crews and resources, and there are so many handoffs between subcontractors, that having everyone committed to the end goal is great. There was a project that I worked on where the concrete subcontractors doing the hospital’s parking garage were failing. They were not making commitments; they were not bringing resources on site. They were constantly trying to utilize the change order process. All the other subcontractors on the team started to realize that they weren’t pulling their weight and they were going to eat up all the float and all the contingency. The other subcontractors stepped in and said, “no, this is our money; this is our schedule; if you need help and you can’t do this, we will get another subcontractor to come in and do the concrete.” They petitioned for the general contractor for approval to use a different concrete subcontractor so that they didn’t lose out on time and money because everyone was sharing the money at the end. It was a really interesting process and illustrated why all projects should utilize IPD. When every stakeholder is fully committed to working toward the goal as a team, projects run much more smoothly.