What is Value Engineering?

Value Engineering (VE) is a phased methodology used to analyze a product, project, or process with the goal of improvement or enhancement without jeopardizing quality or violating any intended functions. VE achieves that goal by assembling a cross-disciplinary team of professionals to analyze project plans and requirements.

VE relies heavily on team building, effective communication, and efficient decision-making to reach creative solutions. By working together, the VE team often arrives at unique approaches to specific design elements that satisfy the owner’s project vision and that save on project cost.

How is it different from Value Analysis? Or Value Methodology?

Value analysis, value methodology, and value engineering are different terms for the same concept.

During World War II, General Electric inaugurated a process they called Value Analysis. Due to the shortage of materials in that period, the company needed to find substitutes. As they found options that were available, cost less, and performed equally well or better, Value Analysis became a process inherent in their operational approach.

The US Navy then realized they could benefit by using Value Analysis and approached General Electric for collaboration with their engineering resources. Following the war, the Navy began to use Value Analysis, taught it to their naval officers, and changed the terminology to Value Engineering.

SAVE International, the organization devoted to advancing and promoting this approach, now use the term Value Methodology. For training purposes SAVE formerly offered Module I and Module II Value Engineering courses. These are now called Value Methodology Fundamentals, a phased approach that must be followed to perform the VE study.

What types of certification do you need to provide Value Engineering?

The first level of certification is the VMA, or Value Methodology Associate, which requires completing a 32-hour course and passing an exam. A Certified Value Specialist, the highest level of certification, requires participating in ten studies, as well as authoring an innovative paper addressing Value Engineering. This is a strenuous process requiring a minimum of two years. These certifications are administered through SAVE International.

What exactly does a ‘Value Engineer’ do?

Basically, Value Engineers perform functional analyses by breaking down the components in the project and identifying the function in each component. They then propose to change, manipulate, or otherwise improve the process, component, or the product itself.

A Certified Value Specialist facilitates the Value Engineering team and leads them through the methodology. Value engineers are also subject matter experts in the disciplines that the particular project requires; for example, a rail project employs experts in signaling, traction power, etc.

Are there different phases to Value Engineering?

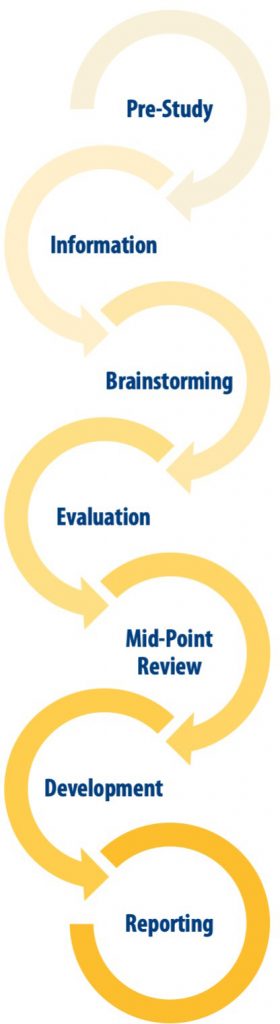

Yes, there is the pre-study phase, in which we solve the logistical problems of where the study will be conducted, what resources are required, etc.

This phase is followed by the study itself, which begins with the information phase. This phase includes two weeks of preparation in which we select people who have had no involvement with the project, so we secure a fresh set of eyes. This phase also includes document review, a presentation from the design consultant who describes the project, decisions, and any commitments, and then a site visit where any new issues and/or constraints, such as an overlooked power line are recorded.

Here we also look at the cost model and perform a functional analysis that requires an active verb and a descriptive noun for every component. We conduct a brainstorming/speculative process, capturing ideas that the team comes up with; we don’t critique or analyze at this juncture. Sometimes the craziest ideas can springboard to something that if you modify with another idea, there will be some feasibility. Therefore, we want to capture all ideas.

The evaluation phase includes a scoring matrix, in which we measure ideas against the design at the 30% design stage. Ideas that are equal to or greater than the basis of design will be considered for development. If there is a fatal flaw, we want to know immediately.

For the mid-point review, we briefly review the ideas that the VE team believes have the potential for development with the owner and their design team. This avoids wasting time developing ideas that may have a fatal flaw that the team wasn’t aware of or an idea that had already been vetted by the designers.

The development phase consists of the VE team looking in depth at each idea from a technical perspective and with an itemization of cost savings or value-added. Each idea is written with a narrative of the original design concept and a narrative of the proposed VE recommendation, along with the advantages and disadvantages of each recommendation.

The reporting phase finalizes the study as recommendations are consolidated as part of a PowerPoint presentation on the final day of the study, and subsequently, a final comprehensive report is transmitted to the owner.

How does Value Engineering improve construction project value?

On a construction study, the Value Engineer looks at improving constructability and saving money. We looked at roadway improvements in the state with a view toward saving money or enhancing the public experience.

Roadway experience is the end product of many internal processes such as transportation system management and operations, consultant acquisition, post-design analysis, etc. Value Engineering improves or adds value to enhance the project so that it is safer or improves the end-user (driver) expectations. For example, many older roadways still use left lane exits. This is contrary to driver expectations today, so they are redesigned accordingly.

PMA has performed several process studies for major state transportation departments. Basically, we broke down the components in the project and identified the function in those components to enhance efficiency and minimize effort and time.

Can VE be disruptive to the design or construction process?

Value Engineering can only be disruptive if done too late and cause re-design costs that may offset project savings, so we recommend it be carried out no later than 30% into the design process.

What are the different types of values in Value Engineering?

Values are defined as cost savings or value added. Value added can result in added costs that will ultimately be beneficial in meeting expectations of end users or save life cycle costs by spending a little more on up-front capital costs.

How does VE reduce waste/delay on a construction project?

Any Value Engineering study should look at constructability as one of the main components. Is there an easier material to install? A faster process? On a construction study, you are primarily looking at constructability and saving money by possibly getting it built more cost-effectively while still satisfying the expectations of owners and project managers. The basis of Value Engineering is to avoid or minimize unnecessary construction costs and delays.

What is a Constructability Review?

As part of construction management, the constructability review determines the feasibility of constructing the project from the plans and specifications and validates schedules and budgets. The phasing, sequencing, and logistics of the project receive specific attention. This effort is aided by the development of a preliminary summary-level schedule.

The review focuses on project coordination, potential liability, and document completeness and consistency. It also eliminates contract language that contributes to unnecessary construction change orders, disputes, and adversarial relationships between the contractor, owner, designer, and project stakeholders.

What types of software do you use for value engineering?

During the VE workshop, we implement NetPoint to communicate the project schedule to all the stakeholders. Compared to P6, NetPoint provides a simpler graphic that can be understood at every level of the project team members. Project activity duration and logic are updated in real-time making it easy to develop what-if scenarios or alternative solutions.

For studies and reports, we use Excel cost sheets embedded in Word templates. The proposed actions, advantages and disadvantages to each alternative, as well as the VE recommendations, are described in a narrative accompanied by a clickable cost analysis spreadsheet. All of this information can be imported into PowerPoint for the final presentation.

Need a VE specialist for your project? Learn more about Richard Johnson on our leadership page.